Autoclave Sterilization Time

Autoclave sterilization is a critical process in various industries, including healthcare, laboratory, and food processing. The autoclave sterilization time is a crucial factor in ensuring the effectiveness of the sterilization process. In this article, we will delve into the world of autoclave sterilization, exploring the factors that affect sterilization time, the different types of autoclaves, and the importance of proper sterilization techniques.

Understanding Autoclave Sterilization

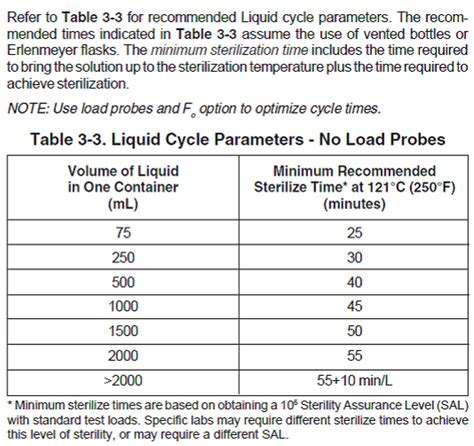

Autoclave sterilization involves the use of high-pressure steam to kill microorganisms, including bacteria, viruses, and fungi. The process typically involves exposing the materials to be sterilized to a temperature of 121°C (250°F) for a specified period, usually between 15 to 30 minutes. The autoclave sterilization time is dependent on several factors, including the type of material being sterilized, the size and shape of the load, and the desired level of sterility.

Factors Affecting Autoclave Sterilization Time

Several factors can affect the autoclave sterilization time, including:

- Material type: Different materials have varying levels of resistance to heat and steam. For example, porous materials such as fabrics and paper products may require longer sterilization times than non-porous materials like glass and metal.

- Load size and shape: The size and shape of the load can affect the distribution of steam and heat, impacting the sterilization time. Larger loads or those with complex shapes may require longer sterilization times to ensure uniform exposure to steam.

- Desired level of sterility: The level of sterility required can impact the autoclave sterilization time. For example, sterilizing medical instruments may require a higher level of sterility than sterilizing laboratory equipment.

Types of Autoclaves

There are several types of autoclaves available, each with its own unique characteristics and advantages. Some of the most common types of autoclaves include:

Gravity displacement autoclaves use gravity to displace air from the chamber, allowing steam to enter and sterilize the load. High-pressure steam autoclaves use a pump to force steam into the chamber, providing faster and more efficient sterilization. Vacuum autoclaves use a vacuum pump to remove air from the chamber, allowing for more efficient steam penetration and sterilization.

Autoclave Sterilization Time Guidelines

The autoclave sterilization time can vary depending on the type of autoclave and the specific application. Here are some general guidelines for autoclave sterilization times:

| Material Type | Sterilization Time (minutes) |

|---|---|

| Non-porous materials (e.g., glass, metal) | 15-20 |

| Porous materials (e.g., fabrics, paper products) | 20-30 |

| Medical instruments | 20-30 |

| Laboratory equipment | 15-20 |

Importance of Proper Sterilization Techniques

Proper sterilization techniques are critical in ensuring the effectiveness of the autoclave sterilization process. This includes:

Load preparation: Ensuring that the load is properly prepared and packaged before sterilization can help prevent contamination and ensure effective sterilization. Autoclave maintenance: Regular maintenance of the autoclave, including cleaning and calibration, can help ensure that the device is functioning properly and providing effective sterilization. Quality control: Implementing quality control measures, such as regular testing and monitoring, can help ensure that the sterilization process is effective and consistent.

Real-World Examples

In the healthcare industry, autoclave sterilization is used to sterilize medical instruments and equipment. For example, a hospital may use an autoclave to sterilize surgical instruments, such as scalpels and forceps, before use. In the laboratory setting, autoclaves are used to sterilize equipment, such as pipettes and petri dishes, to prevent contamination and ensure accurate results.

What is the minimum autoclave sterilization time for medical instruments?

+The minimum autoclave sterilization time for medical instruments is typically 20 minutes at 121°C (250°F). However, this can vary depending on the specific instrument and the manufacturer’s recommendations.

How often should an autoclave be maintained and calibrated?

+An autoclave should be maintained and calibrated regularly, typically every 1-3 months, depending on usage and manufacturer’s recommendations. Regular maintenance can help ensure that the device is functioning properly and providing effective sterilization.

What are the consequences of inadequate autoclave sterilization?

+Inadequate autoclave sterilization can lead to contamination, infection, and other serious consequences. In the healthcare industry, inadequate sterilization can result in patient harm or even death. In the laboratory setting, inadequate sterilization can lead to inaccurate results and compromised research.